Building a Better Dispersant

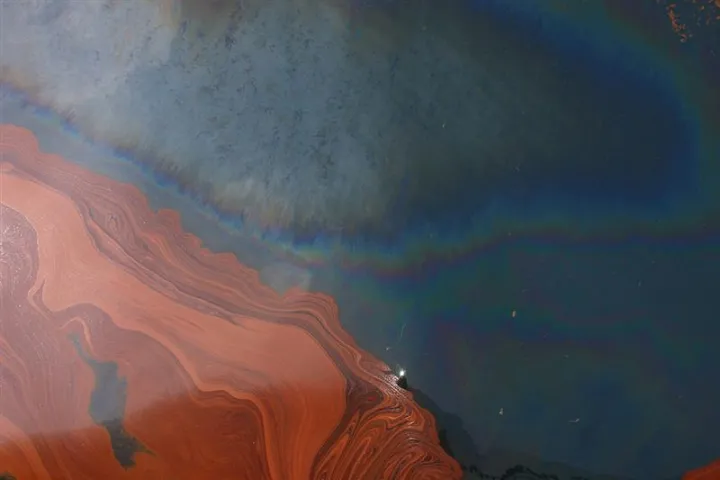

When oil spills in the ocean, slicks are the center of media attention because they do so much immediate harm to wildlife. Oil floating at the surface can harm fish, kill birds, dolphins and turtles, and wash up into marshes, oyster beds, seagrass meadows, and beaches. So when the Deepwater Horizon oil rig exploded 42 miles off the coast of Louisiana, killing 11 people and spewing what would eventually be 3.19 million barrels of oil into the depths of the Gulf of Mexico, responders turned to dispersants. Dispersants are soap-like chemicals used to break up globules of oil by forcing them into a seawater emulsion—similar to the oily mixture you get when making a salad dressing. The animal fats and oils that most household soaps wash away are chemically different than oil, so dispersants are designed specifically for instances when oil and seawater are at play. The smaller droplets of oil remain suspended in the water column where they are more likely to be eaten by oil-degrading bacteria and broken down over time instead of floating to the surface to form a slick.

Acting quickly during spring and summer 2010, clean-up groups applied roughly two million gallons of the dispersant Corexit to the Gulf of Mexico—distributed by planes, boats and even remotely operated vehicles at the leak source some 5,000 feet below the surface. To some, Corexit was the star of the spill, preventing slicks from forming and keeping most of the oil from reaching land.

However, other people did not see it that way. There was widespread public concern when Corexit and other dispersants were deployed in the Gulf because there had been little research on how they impact human and environmental health. Like other soaps, Corexit doesn't harm people in small amounts and is EPA-approved for use as a dispersant after an oil spill. But in large quantities, such as those used during the Deepwater Horizon spill, the EPA recommends that all dispersants be handled with care, including protective clothing and face masks, to reduce inhalation and skin irritation—just in case. Less is known about their environmental effects. Once in the water, small droplets of dispersant and oil are the perfect size for zooplankton to eat. One study found that the combination of oil and Corexit is toxic to the small animals and can impact their growth and behavior, and possibly even be lethal. And after dispersant enters the environment, it doesn't break down easily. Both oil and dispersant were found in deep-sea coral communities six months after the spill and in coastal ecosystems up to two years after, to unknown effect.

So dispersants, which arguably were the heroes of the spill response story, were instead portrayed as the villains, perceived as being more toxic than the oil itself. This doesn’t have to be the case.

A group of engineers, chemists and physicists called “C-MEDS” (short for the Consortium for the Molecular Engineering of Dispersant Systems) funded by the Gulf of Mexico Research Initiative (GoMRI) is seeking to better understand the dispersants we use and searching for the next generation of dispersants that can break up oil slicks more efficiently and with less environmental harm.

One way dispersants could be improved is if they could mix the oil and water better, a method currently under investigation by researchers at the University of Rhode Island. They are studying carbon particles such as carbon black (which is commonly used to strengthen rubber tires and as coloring in cosmetics like mascara), which are non-toxic in small amounts and better at mixing oil and water than Corexit. Carbon has twice the density of water—much denser than current dispersants, which are similar in density to oil (that is, less dense than water). This gives carbon particles a potential advantage. The dense carbon particles attach to oil droplets and cause them to sink for better mixing in the water column. These particles also hold the emulsified oil in the water column for longer, giving oil-eating bacteria more time to chow down before the oil moves to a coast or the ocean floor.

Another way to make dispersants more environmentally friendly is by making them more efficient so that less of them are needed to clean up a spill. One group of researchers from C-MEDs is trying to do just that by using naturally-occurring clay particles made up of tiny hollowed-out tubes. With a diameter of about 20 nanometers (1/1000th the size of a human hair), each tube is filled with the soap-like component of dispersants. When added to a spill, they attach to the interface of oil and water and then release the dispersant into the water slowly, similar to time-release medicines that gradually provide relief over a period of time. Perhaps counterintuitively, this method may require less dispersant overall. When using faster-working dispersants like Corexit, workers apply large quantities to ensure that it reaches all of the spilled oil before washing away. The clay particle dispersant, however, will stick with the oil and water interface for a longer time, ensuring that dispersant is released in the correct area.

The carbon particle and clay nanotube dispersants are two among many options under development. C-MEDS has shown that one of the Corexit chemicals that persists in the environment for the longest—dioctyl sodium sulfosuccinate (DOSS)—can be replaced by a combination of non-toxic food-grade materials, including one used in ice cream. There is also work looking at cactus proteins that can be used in conjunction with traditional dispersants to reduce the amount necessary. And non-toxic versions of herders, which do the opposite of dispersants and form thicker masses of oil, are being considered as a good alternative for spills that occur in cold water where melting fresh water and floating icebergs get in the way.

We don’t have to wait for the next big oil spill to see if these alternatives will do the job. Ron Larson at the University of Michigan has built a complex computer model of how dispersants interact with oil and water at an atomic level. (He built it using Corexit, but plans to create models of dispersant alternatives as well.) The model simulates how Corexit interacts with oil and water, taking "snapshots" every quadrillionth of a second to meticulously observe every movement and interaction between the molecules. By understanding the minute details of Corexit's chemistry, Larson explains, he hopes to get a clearer picture of how effective it is at breaking up oil and, ultimately, how long a dispersant will stay in the ecosystem. This type of modeling could be used to compare the effectiveness of different types of dispersants.

Once the molecular level of a dispersant is modeled and it is tested in a lab, researchers move on to the wave pool. There is no surfing involved; instead, researchers test their dispersants on oil spills in a small wave tank (10 meters (32 feet) long, 1.5 meters (almost 5 feet) wide and deep) like the one at SL Ross, a Canadian consulting firm specializing in oil spills, seen on the left. At Ohmsett (The National Oil Spill Response Research & Renewable Energy Test Facility) there is an even bigger wave pool with a 2.6 million-gallon tank of saltwater. A variety of real-world scenarios can be recreated there including surface spills, with low or high wave action. The carbon black dispersant has been tested at SL Ross with a simulated surface spill and all of the teams hope to do more testing on these larger scales.

After many iterations of this—refining the new dispersants, making molecular models, testing them in the field—the researchers hope to have more efficient and environmentally friendly alternatives for the next oil spill (the risk of which can be reduced but not eliminated). Work at a molecular level is often far-removed from the practical applications of science in real-world scenarios. But in their dispersant research, the C-MEDs research teams are bringing the very theoretical—so-called "ivory tower" or non-applied academic research—to the real world. “We can see that the methods [we are using] are very ivory tower," says Larson. "But now [they are] coming out of ivory tower and out to the oil slick.”

The Ocean Portal receives support from the Gulf of Mexico Research Initiative (GoMRI) to develop and share stories about GoMRI and oil spill science.

The Gulf of Mexico Research Initiative (GoMRI) is a 10-year independent research program established to study the effect, and the potential associated impact, of hydrocarbon releases on the environment and public health, as well as to develop improved spill mitigation, oil detection, characterization and remediation technologies. For more information, visit http://gulfresearchinitiative.org/.